Our Mission

The primary objective of Ro.On is to grant that each project and idea of our customers becomes a reality, providing them with a full partnership, starting from their productive projects, ranging from design to the realisation of the finished product. Thanks to multiple investment the company works with different tool machinery and can offer to its customers different types of processing such as:

- Machining and deformation of the tube starting from dedicated molds

- Dedicated tube cutting lines with tube squaring

- 2D laser tube processing

- CNC tube bending

- Progressive sheet metal molding

- CNC pointing

- Tube painting

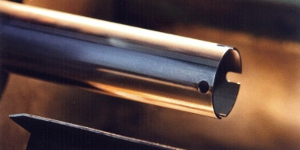

Machining

Mechanized welding

2 Robotic dies, 1 Robot with Rotary Table, 1 Robot with Rotary Self-Stabilising Lathe.

2D laser tube

Maximum working flexibility on tubes and open profiles of various diameters, repeatability constant in time.

CNC tube bending

Left and right fully electric tube bending, high productivity (+ 20%) compared to electro-hydraulic machines.

Tube painting

We offer also tube painting service on request of the customer.

Molding and dedicated machines

30 tons, 40 tons, 60 tons, 80 tons, 100 tons, 120 tons press, 250 tons double column press, transfer tube cutting and squaring.

Copyright © 2012

Copyright © 2012